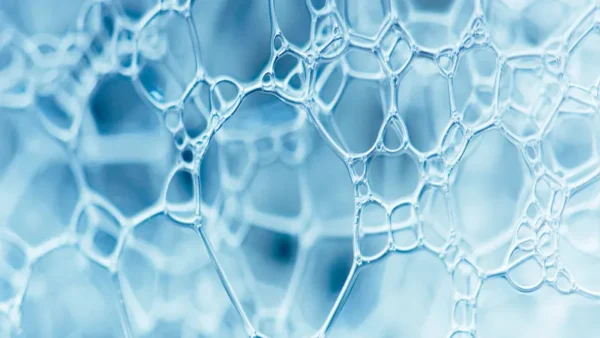

In today’s highly competitive world, the food industry is looking for solutions that not only increase the quality of their products but also reduce production costs. One of the common issues in food production lines is foam formation, which can lead to a decrease in product quality, longer production times, and additional costs. Antifoam in the food industry serves as an effective solution for controlling and reducing foam, playing a vital role in optimizing production processes in the food industry. This article introduces antifoam, its applications, benefits, and how to choose and use it in the food industry to help you select the right product and encourage you to make your purchase from us.

فهرست محتوا

What is Antifoam?

Antifoam or Antifoam is a substance used to control and reduce foam formation in production processes. Foam is a significant problem in many industrial processes, especially in food production, as it can lead to product quality degradation and longer production times.

Types of Antifoam

Antifoams are generally divided into three main categories:

– Silicone Antifoam: This type of antifoam is widely used due to its resistance to temperature and high chemical stability. These products are also suitable for use in systems that come into contact with food materials.

– Water-based Antifoam: These antifoams are ideal for systems that require quick foam removal.

– Oil-based Antifoam: These antifoams are made from mineral or vegetable oils and are used in specific food processes.

Application of Antifoam in the Food Industry

Antifoams have diverse applications in the food industry, especially in processes that deal with liquids. Key applications of antifoam in the food industry include:

- Production of Beverages: In the production line of carbonated or non-carbonated drinks, the use of antifoams prevents unwanted foam from forming, allowing the production process to proceed with better speed and quality.

- Production of Milk and Dairy Products: Antifoams are used in the production lines of milk and dairy products such as yogurt, cheese, and butter to prevent troublesome foam formation and accelerate packaging processes.

- Production of Canned Foods and Ready Meals: In the production of canned food, antifoams help control foam and maintain the quality of the final product.

- Antifoam in Food Industries: In the production of products requiring fermentation processes, such as bread and fermented goods, antifoams help reduce foam and improve fermentation.

Advantages of Using Antifoam in the Food Industry

Using antifoams in the food industry has many benefits that directly affect product quality improvement and cost reduction. Some of these benefits include:

– Reduction in Production Costs: By controlling and reducing foam in various production processes, the time required for producing each product decreases, and costs associated with unwanted production stoppages are reduced.

– Increased Production Efficiency: Antifoams prevent foam formation, allowing machines and equipment to operate more efficiently, and the production line continues without unnecessary interruptions.

– Improved Final Product Quality: Foam in food production can harm the final product and reduce its quality. Using antifoams enhances the final product quality and reduces the likelihood of product rejection.

– Reduced Need for Maintenance: Excessive foam in production lines can damage machines and increase maintenance costs. Antifoams reduce foam, preventing potential damage to equipment.

Choosing the Right Antifoam for the Food Industry

Choosing the right antifoam for the food industry depends on factors such as the type of process, the type of product being produced, and the amount of foam. When selecting an antifoam for use in the food industry, consider the following points:

– Type of Production Process: Depending on whether your production process involves carbonated liquids, fermentation processes, or dairy products, the appropriate antifoam should be selected.

– Food-safe Components: Antifoams used in the food industry must comply with hygiene standards and have no adverse effects on consumer health.

– Resistance to Temperature and Process Conditions: Some food production processes require antifoams that can perform effectively at high or low temperatures.

How to Properly Use Antifoam in Food Production

Proper use of antifoam in the food industry requires following key guidelines to ensure maximum efficiency. Here are some of the important points:

– Optimal Consumption Amount: Using the correct amount of antifoam is very important. If used excessively, it may negatively affect the quality of the final product, and if used too little, foam will not be adequately controlled.

– Timing of Adding Antifoam: The best time to add antifoam in the production process is when foam is beginning to form. This helps prevent additional foam formation.

– Continuous Monitoring of the Process: Continuous monitoring of the production process and the performance of the antifoam is crucial in the food industry. If needed, the amount or type of antifoam can be adjusted.

Why Should You Buy Your Antifoam from Bonyan Shimi?

As a leading supplier of antifoam in the food industry, we provide high-quality products at competitive prices. Our products are manufactured according to international health and safety standards and are made from the best raw materials.

– Guaranteed Quality: All our products are thoroughly tested before being released to the market to ensure their high quality.

– Technical Support: Our technical team is ready to assist you in selecting and optimizing the use of antifoam.

– Competitive Prices: We offer the best prices in the market without compromising product quality.

Conclusion

In conclusion, using antifoam in the food industry is an effective solution for improving production processes, reducing costs, and enhancing the final product quality. Given the widespread applications and benefits of antifoams, their use can directly impact the success of your business. If you are looking to purchase high-quality antifoam at a reasonable price, contact us now and order the product you need.