فهرست محتوا

What is Alcohol-Based Antifoam?

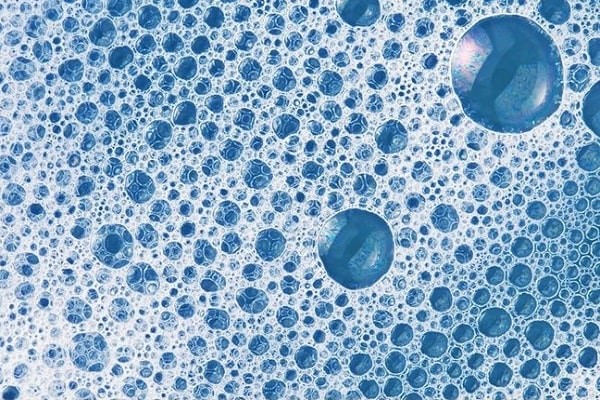

Alcohol-based antifoams are one of the most important and widely used types of defoamers that are used in various industries to control and reduce foam formation. Foam, especially in chemical and industrial processes, can cause serious problems. These problems include reduced production efficiency, decreased product quality, blockage of pipes and equipment, and increased maintenance and repair costs. Therefore, the use of antifoams as an effective and economical solution to control this phenomenon is essential. Bonyan Shimi is a manufacturer of antifoams, making it easier to supply defoamers for industries.

Advantages of Alcohol-Based Antifoam

Alcohol-based antifoams are usually made from heavy alcohols. Due to their unique chemical properties, they are used in many industrial processes. These materials prevent foam formation or quickly break down existing foam by reducing surface tension and rapidly destroying foam bubbles. One of the important advantages of alcohol-based defoamers is their compatibility with various environments and their effective performance under harsh operating conditions, such as high temperatures and varying pH levels.

Alcohol-based antifoams, due to their unique characteristics, are used in various industries, including chemical manufacturing, paper production, paint making, oil refining, and water treatment. In the paper industry, alcohol-based defoamers are used to prevent foam formation at different stages of production. This is because foam can negatively affect the final quality of the paper. Additionally, in the paint industry, foam can cause inconsistencies in color mixing and the formation of unwanted bubbles in the final product, which can be controlled using alcohol-based antifoams.

In oil refining, foam control is particularly important in distillation columns and refining units. This is because foam can reduce separation efficiency and increase energy consumption. Alcohol-based antifoams are widely used in these conditions due to their fast and effective performance. Furthermore, in water and wastewater treatment industries, these materials are used to prevent foam formation in tanks and treatment basins.

Features of Alcohol-Based Antifoam

Alcohol-based antifoams are used in many industries and industrial processes due to their unique characteristics. Some of the main features of alcohol-based antifoams include:

- Rapid foam reduction: Alcohol-based antifoams reduce surface tension, causing foam bubbles to break down quickly. This feature allows these types of antifoams to rapidly and effectively eliminate foam.

- Compatibility with various environmental conditions: Alcohol-based defoamers can operate under harsh conditions such as high temperatures and varying pH levels. This makes them highly suitable for use in industrial environments with changing conditions.

- Good dispersion: These antifoams disperse well in both aqueous and non-aqueous environments. This feature enables them to act quickly and control foam across the environment.

- No negative impact on final products: Alcohol-based defoamers are typically designed not to negatively affect the quality of the final products. This is particularly important in industries like paper production, paint manufacturing, and food processing, where the quality of the final product is crucial.

- Safety and low-risk nature: Many alcohol-based defoamers are designed to be safer compared to other types of antifoams, posing minimal environmental and health risks.

- Adjustable consumption rate: These antifoams typically have adjustable dosages, meaning their consumption rate can be precisely controlled depending on the operational conditions and the amount of foam formed.

In general, alcohol-based antifoams are recognized as an effective solution for foam control in many industries due to their efficient composition and reliable performance. The correct selection of these materials, depending on the type of process and operational conditions, can significantly increase production efficiency and product quality.

Familiarity with the Applications of Alcohol-Based Antifoam

Alcohol-based antifoams, due to their suitable characteristics, have widespread applications in many industries and industrial processes. Some of the most important applications of alcohol-based antifoams include:

Paper and Pulp Industry:

In the paper production process, foam can seriously affect the quality of the final product. Alcohol-based antifoams are used at various stages of paper production, including in pulp processing and paper making, to reduce and control foam. This helps improve the quality of paper and increase production efficiency.

Oil and Refining Industry:

In oil refineries and petrochemical units, foam can cause significant problems in distillation columns and separation units. Alcohol-based antifoams reduce foam formation in these processes, improving separation efficiency and reducing energy consumption.

Paint and Resin Industry:

In the production of paints and resins, foam can cause inconsistencies in the mixture and the formation of unwanted bubbles in the final product. The use of alcohol-based antifoams in this industry helps improve product quality and prevents defects in coatings.

Food and Beverage Industry:

In the production processes of food and beverages, such as fruit juices, carbonated drinks, and canned goods, foam can cause issues such as reduced product quality and undesirable appearance. Alcohol-based antifoams, due to their safety and lack of negative impact on edible products, are widely used in this industry.

Water and Wastewater Treatment Industry:

In water and wastewater treatment processes, foam can reduce treatment efficiency and cause operational problems. Alcohol-based antifoams help improve system efficiency by controlling foam in tanks and treatment basins.

Pharmaceutical Industry:

In the production of medicines and healthcare products, controlling foam is crucial as it can impact the production process and product quality. Alcohol-based antifoams are used in the pharmaceutical industry due to their compatibility with different environments and high safety.

Chemical Industry:

In chemical processes like detergent production, cleaning agents, and other chemical products, foam can cause problems such as pipe blockages and reduced production efficiency. Alcohol-based antifoams are used in this industry to prevent foam formation and improve process performance.

Fermentation Processes:

In fermentation processes, used in the production of products like alcohols and biotechnology, foam can reduce efficiency and increase operational problems. Alcohol-based antifoams help reduce foam formation in these processes, boosting efficiency.

In general, alcohol-based antifoams are widely used in a range of industries due to their effectiveness and safety, playing a key role in improving process efficiency and the quality of final products.

Conclusion

In the end, alcohol-based anti-foams are recognized as an effective and efficient solution for controlling and reducing foam in many industries. These materials, due to their unique features such as fast action, compatibility with various operational conditions, and no negative impact on the quality of final products, have a special place in production and industrial processes.

The correct selection and proper use of alcohol-based anti-foams can lead to improved production efficiency, reduced operational costs, and enhanced final product quality. In today’s world, where process optimization and efficiency are of great importance, the use of these materials is a necessity for many industries.